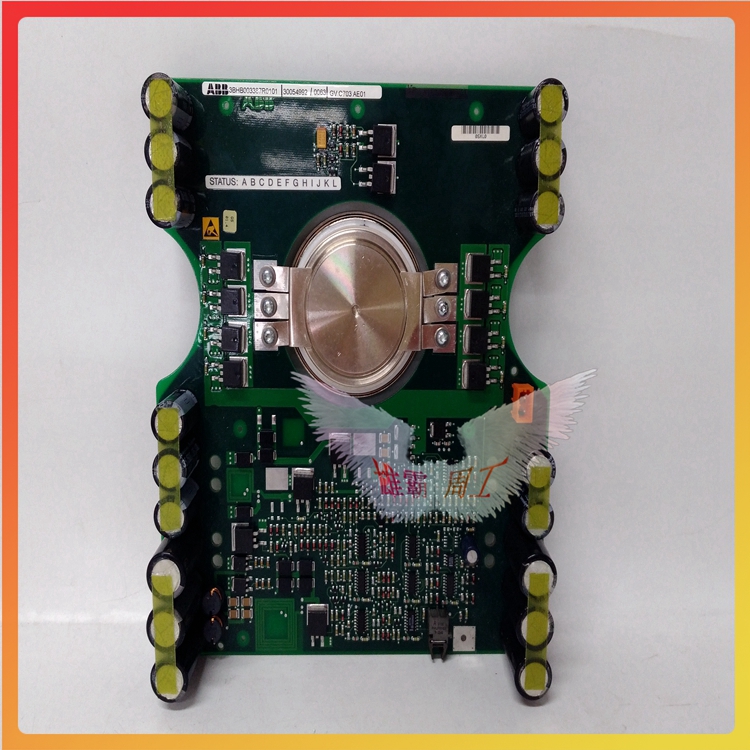

ABB Distributed control system DCP02 programmable logic controller

Brand ABB Color Standard Application Industrial height 355mm rated current 460mA

Protection level IP45 Suitable for motor power 36KW Application Site Power Industry Material Code GJR2391500R1220 Power industry HIEE401782R0001 Part Number DCP02

Applicable pipe 2 Whether imported is weighing 6.88 kg can be sold nationwide

ABB Distributed control system DCP02 programmable logic controller

System 800xA supports two different types:

The PROFIBUS DP scales up to 12 Mbit/s and is optimized for interaction with devices such as remote I/O, drives and motor controls.

With a fixed transfer rate of 31.25 kbit/s, PROFIBUS PA is designed to connect bus-powered two-wire field devices such as transmitters and actuators, including information system applications.

System 800xA supports the entire PROFIBUS system architecture in the following ways:

Redundant connection AC 800M controller with PROFIBUS DP

Higher availability of infrastructure and network equipment

OPC server for applications such as 800xA asset optimization or operations

The full range of field equipment is certified to work with System 800xA for seamless implementation

The System 800xA Device Integration package for PROFIBUS provides the necessary components needed to manage field devices in an 800xA system environment, including:

A comprehensive device library of ABB and third-party device type objects

Fieldbus management tool for configuration, parameterization, debugging, and detailed diagnostics

Fieldbus OPC servers provide field equipment variables and status information for asset optimization applications and operator workplaces

Asset monitors analyze asset status and condition information

Equipment vendors can rest assured that their equipment and associated software components will function properly with the 800xA system throughout its lifecycle. System users will benefit from reduced engineering time, reduced commissioning time and reduced maintenance costs. ABB will benefit from reduced engineering and troubleshooting efforts. The result will be a more efficient use of fieldbus technology.

Throughout the plant and its entire life cycle, all relevant equipment status, diagnostic and process information is available whenever necessary. The right information at the right place at the right time.

In addition, ABB has added value to the Profibus library by making the asset management component a standard feature. This enables end users to identify maintenance issues, diagnose root causes of problems, and provide corrective advice before they occur.

ABB Distributed control system DCP02 programmable logic controller

ABB 07KT97B

ABB 07KT97F1

ABB 200900-004

ABB 35AE92

ABB 3BHB003689

ABB 3HAB3700-1

ABB 3HAB8101-8/08Y

ABB 3HAC025466-001

ABB 3HAC031683-001

ABB 3HAC14550-2/09A

ABB 3HAC14550-4/04B

ABB 3HAC17326-1/02

ABB 3HAC17346-1/01

ABB 3HAC4776-1/1

ABB 3HNA000512-001

ABB 3HNE00313-1

ABB 61615-0-1200000

ABB AI610

ABB AI835

ABB AX411/50001

ABB BB510

ABB CI520V1

ABB CI610

ABB CI615

ABB CI626