5SGY3545L0020 High speed pulse unit module ABB

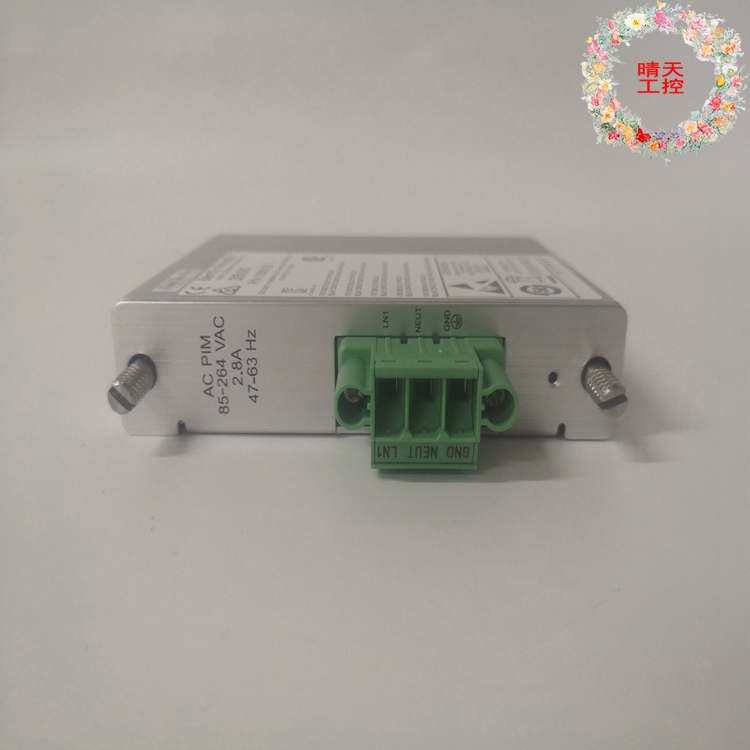

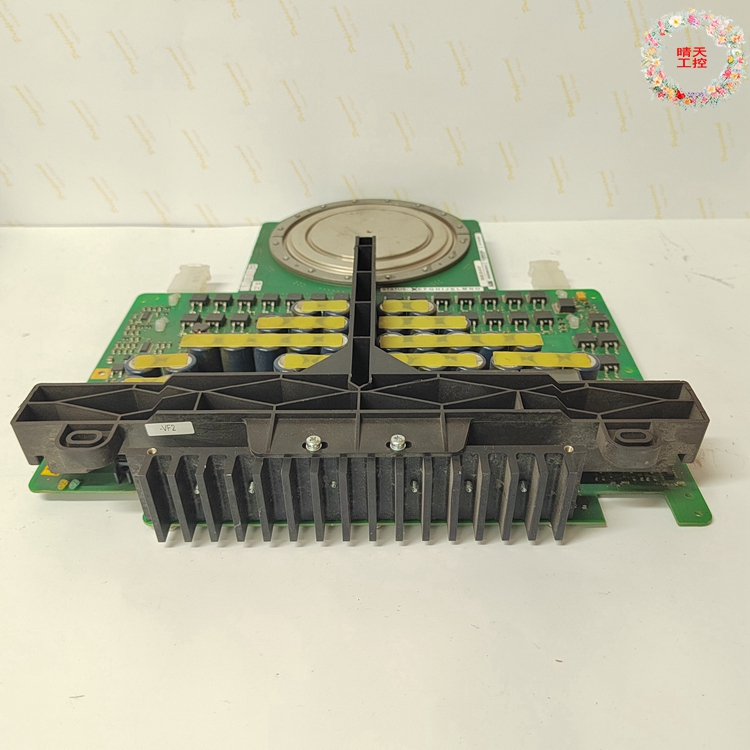

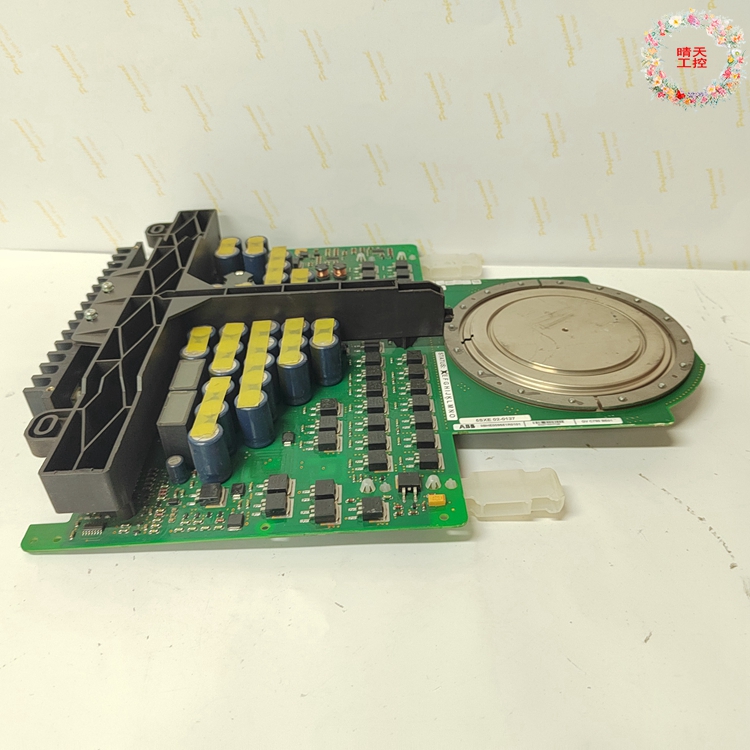

Brand ABB Color Standard Application Industrial height 235mm rated current 450mA

Protection Level IP45 Suitable for motor power 66KW Application Site Power Industry Material Code GJR2391500R1220 Power industry HIEE401782R0001 Part No. 5SGY3545L0020

Applicable pipe 2 Whether imported is weighing 5.88 kg can be sold nationwide

5SGY3545L0020 High speed pulse unit module ABB

Maintenance safety: Safety considerations during routine maintenance and overhaul:

This mainly includes routine maintenance and inspection, spare parts reserve, and timely treatment after failure:

(1) Daily maintenance: In order to ensure the normal operation of DCS, the premise is that the system has a compliant operating environment, which is mainly reflected in the ambient temperature range and air cleanliness in the machine room. The optimal operating temperature of the DCS system should be maintained within the range of 23±2 ° C. Clean air can avoid poor ventilation, bringing heat dissipation equipment, especially large capacity power supply and CPU card and other equipment surface temperature is too high, resulting in system power failure or downtime. To this end, the daily spot inspection should focus on checking the operating status of air conditioning equipment, power supply equipment and fans (including the internal fan of the power supply), and regularly cleaning the filter equipment. By looking (to see whether the status indicator is normal), listening (to hear whether the power supply and fan run abnormally), and hand model (to touch the power supply surface to check whether the temperature is abnormal), you can detect potential faults in advance and take timely measures to avoid accidents.

(2) System configuration modification: In the process of system operation, try to avoid configuration modification. After the system configuration must be modified and installed for some reasons, the system should be backed up in time to avoid the mismatch between the real-time controller database and the backup database of the engineer station when a hard disk fault cannot be recovered. In this case, the database refuses to modify the problem. In this case, the system can only be downloaded offline.

(3) Reserve of spare parts: according to the maintenance experience and routine situation of the same DCS system, the appropriate type and quantity of spare parts should be ordered when the system is ordered. However, due to the uncertainty of the system fault type in the actual process, the problem of unbalanced spare parts reserve may be caused. Therefore, it is necessary to fill the reserve of spare parts at any time according to the actual consumption of spare parts during the DCS system maintenance process. However, in general, all types of power supplies, dedicated fans and backup batteries, controller CPU cards, I/OLINK cards, peripheral cards, I/O cards, especially control cards, operating station CPU cards, dedicated displays, etc., should be guaranteed at least one spare part. Special attention should be paid to the dedicated system hard disk, which should ensure that there is a system boot hard disk backup to avoid the paralysis of the entire system due to the damage of the system boot hard disk that cannot be recovered technically.

(4) Timely handling of faults: This involves the cycle and time of daily inspection. Since most of them now implement the requirement of one inspection per normal working day, there is a dead zone of inspection maintenance within 24 hours and 48 hours on statutory rest days. Therefore, the safety monitoring of the dead-time system must be completed with the assistance of the operator. The main equipment and card of the image system can be monitored through the alarm status of the system. The operating condition of the air conditioning equipment can be monitored indirectly by the operator through the thermometer. For the power supply, fan equipment will not be able to complete the monitoring, therefore, maintenance personnel can try to some equipment equipped with external contact point alarm through the form of digital I/O, such as DCS system, to establish a separate monitoring screen by the operator to monitor.

After discovering or receiving system fault information, maintenance personnel should handle the fault in time. For faults that may affect the entire system security, two or more people should negotiate to handle the faults to avoid human errors. At the same time, the use of anti-static bracelets and similar devices is a must to prevent damage to devices with integrated circuits.

It can be said that as long as the above three links pay attention to and deal with the safety of the DCS system, to avoid man-made equipment hazards, coupled with the high reliability of the DCS system itself, the safety of the DCS system will have a more reliable guarantee, and the application and development prospects of the DCS system will be bright.

5SGY3545L0020 High speed pulse unit module ABB

ABB PM632

ABB PM645B

ABB PS130/6-75-P

ABB RF615

ABB SAFT103

ABB SAFT110

ABB SB512

ABB SC513

ABB SE96920414 YPK112A

ABB SNAT617CHC

ABB SPA-ZC22

ABB SPAD346C

ABB SPCJ4D34-AA

ABB TA524

ABB TB521-ETH

ABB TC625

ABB TC630

ABB TET106 11355-0-6050000

ABB TK516

ABB TU515